Glass surface polishing

We would like to introduce our surface polishing technology.

By polishing to the thickness specified by our customers, the surface of our final products will become a high-quality mirror form.

In addition, ultra-precision polishing processing, high precision quality which optical glasses requested is also available.

By polishing to the thickness specified by our customers, the surface of our final products will become a high-quality mirror form.

In addition, ultra-precision polishing processing, high precision quality which optical glasses requested is also available.

Advantages

Polishing high quality glasses such as optical glass, colored glass and cover glass for high-pixel camera modules (appearance defects quality control start from 3Êm level).

High precision (flatness, parallelism, surface roughness).

High quality US cleaning

Available with various thickness

Small lot prototype processing is welcomed

Quality assurance by various types of measurement such as Laser-Microscopic, Laser interferometer, Haze measuring machine, Spectrophotometer.

As an outsourcer to support your glass processing (from prototype to mass production).

High precision (flatness, parallelism, surface roughness).

High quality US cleaning

Available with various thickness

Small lot prototype processing is welcomed

Quality assurance by various types of measurement such as Laser-Microscopic, Laser interferometer, Haze measuring machine, Spectrophotometer.

As an outsourcer to support your glass processing (from prototype to mass production).

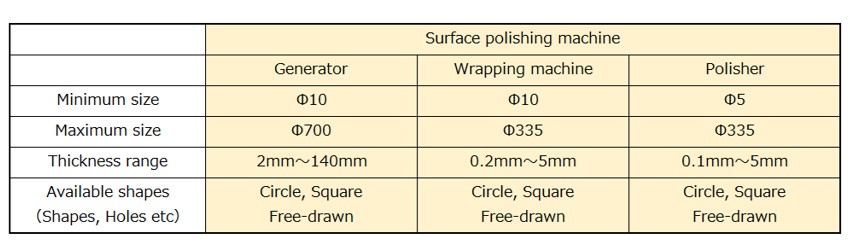

Process & Equipment

Applications

Cover glass with extremely no scratches or appearance defects

Cover glass for image sensors (CMOS, CCD, etc.), optical glass filter (IR / UV, etc.), cover glass for camera modules

(Digital cameras, In-vehicle cameras, industrial cameras, surveillance cameras, distance measurement/image recognition cameras), and other optical equipments, optical communication devices, etc.

High flatness and high definition glass

In-vehicle cover glass, optical communication devices, optical substrate, projector, projection mapping, small and medium-sized flat display, LED cover glass, cover glass for semiconductor`s laser beam, glass substrates, and the other cover glasses.

0.1mm Ultra-thin polished glass

IR / UV filter glass, cover glass for optical devices, glass for various coatings, filter glass for optics, glass spacers, etc.

Cover glass for image sensors (CMOS, CCD, etc.), optical glass filter (IR / UV, etc.), cover glass for camera modules

(Digital cameras, In-vehicle cameras, industrial cameras, surveillance cameras, distance measurement/image recognition cameras), and other optical equipments, optical communication devices, etc.

High flatness and high definition glass

In-vehicle cover glass, optical communication devices, optical substrate, projector, projection mapping, small and medium-sized flat display, LED cover glass, cover glass for semiconductor`s laser beam, glass substrates, and the other cover glasses.

0.1mm Ultra-thin polished glass

IR / UV filter glass, cover glass for optical devices, glass for various coatings, filter glass for optics, glass spacers, etc.

Availability

|