Inspection/Measurement

MATSUNAMI has various methods to inspect our final productions in order to secure our quality.

In response to each company's requirement, we apply various tests such as environmental test, complicated shape measurement, spectrum measurement and etc.

In addition, visual inspection addressed in our clean room enable us to deliver our products (CMOS and other sensor cover glass) without defects more than 3Êm level. Various visual inspection standards are set at MATSUNAMI.

In response to each company's requirement, we apply various tests such as environmental test, complicated shape measurement, spectrum measurement and etc.

In addition, visual inspection addressed in our clean room enable us to deliver our products (CMOS and other sensor cover glass) without defects more than 3Êm level. Various visual inspection standards are set at MATSUNAMI.

Advantages

Clean room overview: 1000 class level (10 Class level for clean booth)

Inspection method for glass surface and interior

E High-brightness light inspection for micro defects (10,00 ~300,000 lux)

E Visual inspection with fluorescent lamp (600~8,000 lux)

E Microscopy inspection

E Automation inspection line

E CCD image inspection

Inspection method for glass interior, pulse defect, surface unevenness

E Image inspection(Collimator lens)

E Xenon irradiation test

E Strain inspection

Inspection method for glass surface and interior

E High-brightness light inspection for micro defects (10,00 ~300,000 lux)

E Visual inspection with fluorescent lamp (600~8,000 lux)

E Microscopy inspection

E Automation inspection line

E CCD image inspection

Inspection method for glass interior, pulse defect, surface unevenness

E Image inspection(Collimator lens)

E Xenon irradiation test

E Strain inspection

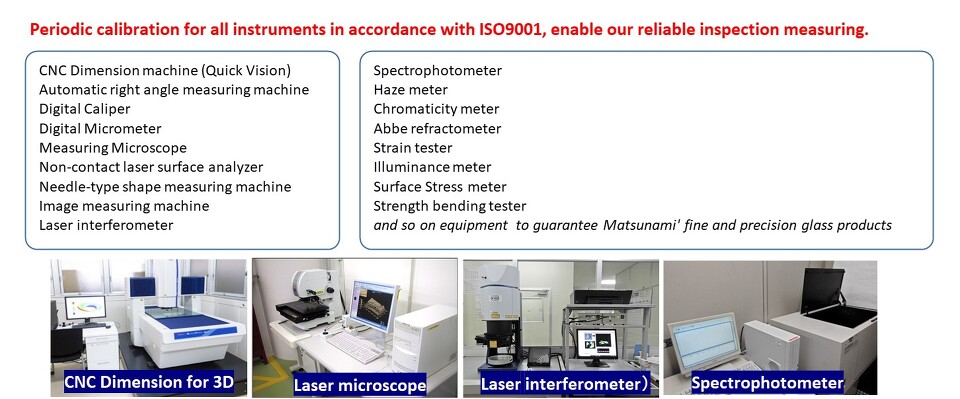

Inspection equipment

1 Matsunami Master System; only qualified and limited inspectors are allowed to conduct visual inspection.

2 Meet inspection needs for 3Êm~20Êm level defects for products such as optical glass, cover glass for camera module.

3 Various methods tackle various inspection needs.

4 Clean room packaging guarantee our glass without any dust

5 Wide range of size is available (from certain mm level to FPD size)

6 Automation inspection is also available for mass production

2 Meet inspection needs for 3Êm~20Êm level defects for products such as optical glass, cover glass for camera module.

3 Various methods tackle various inspection needs.

4 Clean room packaging guarantee our glass without any dust

5 Wide range of size is available (from certain mm level to FPD size)

6 Automation inspection is also available for mass production

Measurement equipment

Sensing, imaging, optical communication components, light field display

Refractive lenses, diffusion screen, anti-reflection, etc.

Refractive lenses, diffusion screen, anti-reflection, etc.

Availability

SHAPE: Thickness, dimension, deformed contour shape, thread surface, corner, squareness, circle, 3D shape

SURFACE: Roughness, waviness, flatness, parallelism, wavefront aberration, contact angle

OPTICAL PROPERTY: Transmittance, reflectance, haze, refractive index(abbe number), glass strain(internal stress)

THERMAL PROPERTY: Thermal expansion, glass thermal characteristics(softening point, transition rotation, strain point, slow cooling rotation)

MECHANICAL PROPETRY: Hardness, breaking strength(bending, falling ball test), strengthening stress(CS/DOL)

RELIABILITY: Constant temperature and humidity test, high temperature, low temperature, heat cycle test

SURFACE: Roughness, waviness, flatness, parallelism, wavefront aberration, contact angle

OPTICAL PROPERTY: Transmittance, reflectance, haze, refractive index(abbe number), glass strain(internal stress)

THERMAL PROPERTY: Thermal expansion, glass thermal characteristics(softening point, transition rotation, strain point, slow cooling rotation)

MECHANICAL PROPETRY: Hardness, breaking strength(bending, falling ball test), strengthening stress(CS/DOL)

RELIABILITY: Constant temperature and humidity test, high temperature, low temperature, heat cycle test

|