Imprinting

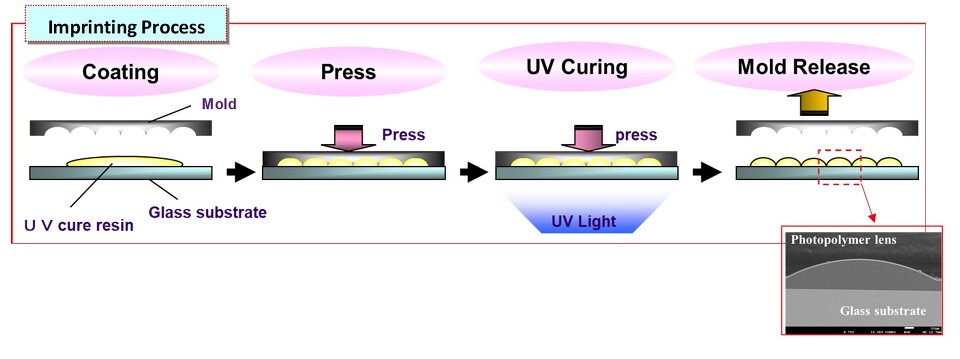

MATSUNAMI has imprint technology to form a fine structure on the glass surface.

Using an ultra-high-definition mold, it is possible to directly mold nano/micro order resin microstructures on various glass substrates with high precision.

Also, by adopting our original optical resin, it is possible to reach various optical characteristics and reliability.

Using an ultra-high-definition mold, it is possible to directly mold nano/micro order resin microstructures on various glass substrates with high precision.

Also, by adopting our original optical resin, it is possible to reach various optical characteristics and reliability.

Advantages

Fusion of the features of glass and resin

1) Glass-Resin complex structure; combination of environmental resistance / thermal stability of glass and easy molding of resin.

2) 1/10 or less on dimensional change; compare to All-Resin products, Glass-Resin are stable.

3) 1/5 or less on cost; compare to All-Glass products, Glass-Resin are cheaper.

4) Stability even in 85~85%_1000hrA85Ì-40_1000cycle environmental test.

Realization of ultra precision microstructure

1) Fine structure with high dimensional accuracy is achieved by ultra-high-definition mold.

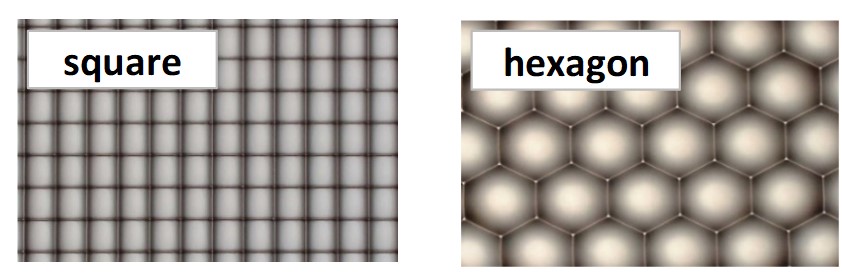

2) Various shapes including cylindrical, hexagon, square, circle, convex and concave, etc.

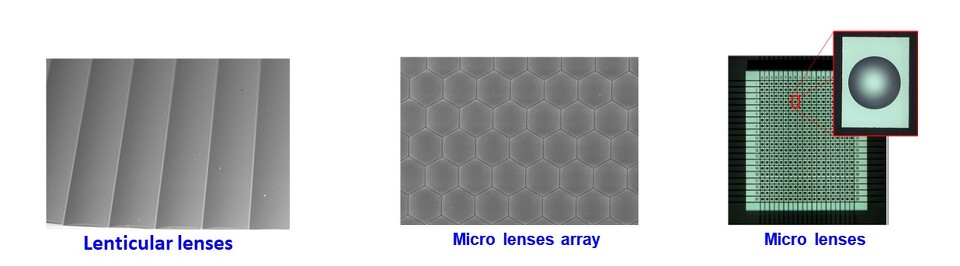

3) Applications including aspherical lenses, Toroidal lenses, Fresnel lenses, gratings, moss eyes, etc.

1) Glass-Resin complex structure; combination of environmental resistance / thermal stability of glass and easy molding of resin.

2) 1/10 or less on dimensional change; compare to All-Resin products, Glass-Resin are stable.

3) 1/5 or less on cost; compare to All-Glass products, Glass-Resin are cheaper.

4) Stability even in 85~85%_1000hrA85Ì-40_1000cycle environmental test.

Realization of ultra precision microstructure

1) Fine structure with high dimensional accuracy is achieved by ultra-high-definition mold.

2) Various shapes including cylindrical, hexagon, square, circle, convex and concave, etc.

3) Applications including aspherical lenses, Toroidal lenses, Fresnel lenses, gratings, moss eyes, etc.

Process

Applications

Sensing, imaging, optical communication components, light field display

Refractive lenses, diffusion screen, anti-reflection, etc.

Refractive lenses, diffusion screen, anti-reflection, etc.

Specifications

1) Maximum Size: 400*400mm

2) Substrate: various glass, film (0.1mm~2.0mm thickness)

3) Refractive index: 1.4~1.7

4) Single/double side molding, various coatings, and irregular shapes/drilling, etc.

2) Substrate: various glass, film (0.1mm~2.0mm thickness)

3) Refractive index: 1.4~1.7

4) Single/double side molding, various coatings, and irregular shapes/drilling, etc.

|