Ultrasonic precision cleaning

MATSUNAMI possesses various types of Ultrasonic precision cleaning technologies.

In response to each customer`s specified request, we provide our cleaning service to meet customer's needs.

Ultrasonic cleaning lines enable our cleaning process from the beginning to the end including cleaning, rinsing, drying and inspecting.

Processed glass will be automatically moved into clean room, and then be delivered to customers without any concern on glass appearance defect.

In response to each customer`s specified request, we provide our cleaning service to meet customer's needs.

Ultrasonic cleaning lines enable our cleaning process from the beginning to the end including cleaning, rinsing, drying and inspecting.

Processed glass will be automatically moved into clean room, and then be delivered to customers without any concern on glass appearance defect.

Advantages

High quality for optical colored glass, cover glass for high-pixel camera modules which request 3 Êm appearance quality guarantee.

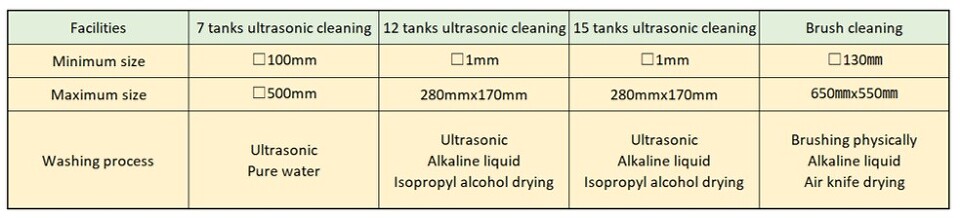

Various size, thickness, small lot of sample trial are available.

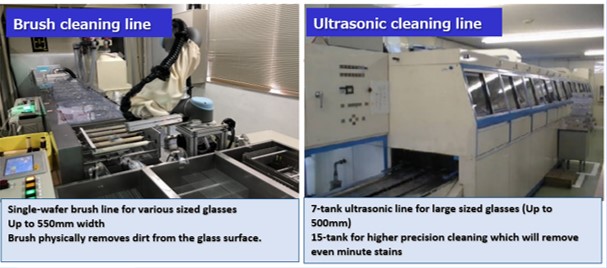

Ultra-precision ultrasonic cleaning and single-wafer brush cleaning are available; according to product features and customer requirements.

Maintain high wettability on the glass surface after cleaning.

Various stains such as particle stains, organic stains, and inorganic stains will be removed.

We also undertake contract processing of specified glass (from trial to mass production).

Various size, thickness, small lot of sample trial are available.

Ultra-precision ultrasonic cleaning and single-wafer brush cleaning are available; according to product features and customer requirements.

Maintain high wettability on the glass surface after cleaning.

Various stains such as particle stains, organic stains, and inorganic stains will be removed.

We also undertake contract processing of specified glass (from trial to mass production).

Process & Equipment

Applications

It is possible to finish an extremely clean glass surface without scratches, appearance defects, or dust.

Cover glass for image sensors (CMOS, CCD, etc.), Optical glass filter (IR / UV, etc.), Cover glass for camera modules (Digital cameras, in-vehicle cameras, industrial cameras, surveillance cameras, distance measurement, image recognition cameras), optical equipment, optical communication devices and so on

Cover glass for image sensors (CMOS, CCD, etc.), Optical glass filter (IR / UV, etc.), Cover glass for camera modules (Digital cameras, in-vehicle cameras, industrial cameras, surveillance cameras, distance measurement, image recognition cameras), optical equipment, optical communication devices and so on

Availability

|